Aloma Wright: Unpacking The Story Of Aloma Shim And Manufacturing

When you hear "Aloma Wright," you might first think of a person, perhaps a familiar face from television or film. Yet, there's another compelling story connected to that name, one that plays a very important role in the world of precision manufacturing. This article will explore "Aloma Wright" not as an individual, but as the foundational name behind a company that has been a quiet force in industrial supply for decades. It's almost fascinating to see how a name can resonate in different ways, isn't it?

Based on the information we have, the name "Aloma" is deeply tied to the "Aloma Shim and Manufacturing Company." This business has carved out a significant niche, providing essential components and services to various industries. They are, in a way, the unsung heroes behind many complex machines and structures, making sure everything fits just right.

So, if you're curious about the intricate details of industrial components, or perhaps how a company builds a reputation for quality and precision over many years, then you're in the right spot. We'll take a look at what makes Aloma Shim and Manufacturing stand out, and how they meet the often very specific needs of their customers.

Table of Contents

- Aloma Shim and Manufacturing: A Company Profile

- Materials of Precision: What Aloma Offers

- The Strength of 304 Stainless Steel

- Understanding Carbon Steel for Durability

- Brass: A Versatile Choice

- Color-Coded Plastic and Laminated Materials

- Cutting-Edge Services for Custom Needs

- Laser Cutting Services: Sharp Accuracy

- Water Jet Cutting: Precision with Power

- CNC Machining: Automated Excellence

- Contract Manufacturing: A Partnership for Production

- A Customer-Focused Approach and Digital Presence

- Frequently Asked Questions About Aloma

- Conclusion

Aloma Shim and Manufacturing: A Company Profile

While the keyword "Aloma Wright" might lead some to think of a person, the core information we're exploring here points to a long-standing entity in the manufacturing sector. The "Aloma Shim and Manufacturing Company" has been a consistent presence in its field since its inception. It's really quite something to consider a business thriving for so long, isn't it?

Given that our information describes a company and its operations, a personal biography table isn't applicable. Instead, we can outline some key details about the Aloma Shim and Manufacturing Company itself, drawing from the provided text. This gives us a clearer picture of their operational history and focus.

| Company Name | Aloma Shim and Manufacturing Company |

| Founded | 1982 |

| Primary Products | Shims, Shim Kits, Finished Fabricated Parts |

| Key Materials Offered | 304 Stainless Steel, Carbon Steel, Brass, Color-Coded Plastic, Various Laminated Materials |

| Core Services | Laser Cutting, Water Jet Cutting, CNC Machining, Contract Manufacturing, Custom Lengths/Widths |

| Online Presence | aloma.com |

This table, in a way, provides a snapshot of their identity and what they bring to the table. It's quite clear they specialize in precision components, and that's a very specific kind of expertise.

Materials of Precision: What Aloma Offers

A company's strength often comes from the quality and variety of materials it works with. Aloma Shim and Manufacturing clearly understands this, offering a comprehensive range of options to meet diverse industrial needs. They stock materials that are known for their specific properties, which is actually pretty important for custom work.

The Strength of 304 Stainless Steel

Aloma provides 304 stainless steel, which is a very popular choice in many industries. This type of stainless steel is known for its excellent corrosion resistance, making it ideal for environments where rust or degradation could be an issue. It also has good formability and weldability, meaning it can be shaped and joined relatively easily, which is quite useful for creating precise shim stock and other fabricated parts.

Using 304 stainless steel in shims ensures that these critical components maintain their integrity and precise dimensions even when exposed to moisture, chemicals, or other harsh conditions. This durability is, you know, a major benefit for long-term performance in machinery and equipment. It's a material that tends to be very reliable.

Understanding Carbon Steel for Durability

Another material Aloma keeps on hand is carbon steel. This material is valued for its strength and hardness, making it suitable for applications where components need to withstand significant wear and tear. Carbon steel shims can provide robust support and precise alignment in heavy-duty machinery, offering a dependable solution where high load-bearing capacity is required.

The choice of carbon steel speaks to Aloma's understanding that different applications demand different material properties. For situations where sheer strength and resistance to deformation are paramount, carbon steel is often the material of choice. It's a very practical option for certain jobs, apparently.

Brass: A Versatile Choice

Brass is also part of Aloma's material selection. This alloy of copper and zinc offers a unique combination of properties. It has good electrical conductivity, excellent machinability, and a relatively low friction coefficient. These characteristics make brass shims suitable for applications where electrical grounding is needed, or where components need to slide smoothly against each other without excessive wear.

The use of brass shows a commitment to providing solutions for a wide array of technical requirements, not just strength or corrosion resistance. It's a rather versatile material, which is good for diverse customer needs.

Color-Coded Plastic and Laminated Materials

Beyond metals, Aloma also offers color-coded plastic and a variety of laminated materials. Plastic shims are often used for insulation, vibration dampening, or in environments where metal-to-metal contact needs to be avoided. The color coding helps with easy identification of thickness, which is a very helpful feature for assembly lines and maintenance crews.

Laminated materials, on the other hand, are quite interesting. They consist of multiple thin layers that can be peeled away to achieve a precise thickness. Aloma provides various types, including Polyimide plastic (comp 6), all laminations (type 1), 1/2 solid/1/2 laminated (type 2), .002 laminations (class 1), and .003 laminations (class 2). This versatility in laminated options allows for extremely fine adjustments and reduces the need for multiple fixed-thickness shims, making them very efficient for precise installations. It's a bit like having a customizable shim on demand.

Cutting-Edge Services for Custom Needs

Having a wide range of materials is one thing, but being able to process them with precision is another. Aloma Shim and Manufacturing offers several advanced cutting and manufacturing services, ensuring they can deliver parts exactly to customer specifications. This capacity for custom work is, you know, a big part of their value proposition.

Laser Cutting Services: Sharp Accuracy

Laser cutting is one of the services provided by Aloma. This technology uses a high-powered laser beam to cut materials with extreme accuracy and clean edges. It's particularly useful for intricate designs and when tight tolerances are required. For shims and other fabricated parts, laser cutting ensures that each piece is uniform and fits perfectly, which is pretty essential for performance.

The precision of laser cutting also means less material waste, and it can handle a wide range of material thicknesses. This capability allows Aloma to produce complex shapes and designs that might be difficult or impossible with traditional cutting methods. It's actually a very efficient way to create precise components.

Water Jet Cutting: Precision with Power

Another cutting service offered is water jet cutting. This method uses a high-pressure stream of water, often mixed with abrasive particles, to cut through virtually any material. Unlike laser cutting, water jet cutting doesn't generate heat, which is very important for materials that could warp or change properties when exposed to high temperatures. This means it's suitable for a broader range of materials, including some plastics and composites.

Water jet cutting allows for highly accurate cuts without affecting the material's structural integrity. This makes it a good choice for sensitive applications where material properties must remain unchanged. It's a powerful tool for achieving specific shapes and sizes, even for thick materials, which is quite impressive.

CNC Machining: Automated Excellence

Aloma also provides CNC machining. CNC stands for Computer Numerical Control, meaning machines are programmed to perform precise cutting, drilling, and shaping operations automatically. This automation ensures high repeatability and consistency, which is crucial for producing large quantities of identical parts with very tight tolerances. It's a rather modern approach to manufacturing.

CNC machining allows for the creation of complex three-dimensional parts with exceptional accuracy. This capability supports Aloma's ability to provide "finished parts to your specifications," going beyond just shims to offer a broader range of fabricated components. It's basically a way to ensure every piece is made exactly right, every time.

Contract Manufacturing: A Partnership for Production

Beyond individual services, Aloma offers contract manufacturing. This means they can take on the production of components or assemblies for other companies. Businesses can outsource their manufacturing needs to Aloma, leveraging their expertise, equipment, and material stock without having to invest in their own facilities. This can be a very cost-effective solution for many companies, reducing their overhead and production time.

Contract manufacturing often involves a close partnership, where Aloma works with clients to understand their specific product requirements and deliver high-quality parts on schedule. This service underscores their role as a reliable partner in the supply chain, providing comprehensive solutions from design to finished product. It's a pretty big help for businesses looking to streamline their operations.

A Customer-Focused Approach and Digital Presence

The "Aloma Shim and Manufacturing Company" doesn't just focus on materials and machinery; they also place a strong emphasis on customer interaction. Their approach to online engagement is quite interesting, reflecting a desire to assist customers much like in a traditional retail setting. They have, in a way, brought the human touch to their digital platform.

Aloma.com is designed to be a leading resource for shims and fabricated parts. The company states they "try hard to make aloma.com the best shim and fabricated parts site on the web." This ambition is supported by their use of "live representatives" who can "monitor our customers as they browse the site and approach those customers who seem to need assistance." This proactive customer service model aims to replicate the helpfulness of an in-person shopping experience, which is actually quite forward-thinking for an industrial supplier.

This focus on customer experience suggests a company that values feedback and continuous improvement. They explicitly state, "Your views on what we're doing and how we could make things even better are important to us." This open communication channel helps them refine their offerings and ensure they remain responsive to the evolving needs of their clients. It’s pretty clear they want to get things right for their users.

For those looking for specific details or to place orders, Aloma provides various ways to connect. While their website is a primary point of contact, they also mention a fax number (412), indicating they maintain traditional communication channels as well. This blend of modern digital interaction and established methods shows a practical approach to accessibility. Learn more about Aloma's offerings on our site, and link to this page here.

Frequently Asked Questions About Aloma

People often have specific questions when looking for specialized manufacturing services or components. Here are some common inquiries that might arise about Aloma Shim and Manufacturing, based on their described operations.

What types of materials does Aloma specialize in for shims and fabricated parts?

Aloma specializes in a wide range of materials, including 304 stainless steel, carbon steel, brass, color-coded plastic, and various laminated materials. These choices allow them to meet diverse application needs, from corrosion resistance to high strength, which is pretty comprehensive.

What unique services does Aloma offer beyond standard shim production?

Beyond standard shim production, Aloma offers advanced services like laser cutting, water jet cutting, and CNC machining. They also provide contract manufacturing, which means they can produce custom finished parts to specific client designs. This is quite a broad set of capabilities, really.

How does Aloma ensure customer satisfaction and support online?

Aloma aims to provide excellent customer support by having live representatives monitor their website. These representatives can proactively reach out to customers who seem to need assistance, much like in a retail store. They also value customer feedback to improve their services, which is quite a thoughtful approach.

Conclusion

The name "Aloma Wright," when considered in the context of our information, points to the significant contributions of the Aloma Shim and Manufacturing Company. Since 1982, this company has consistently provided precision shims and fabricated parts, using a diverse array of materials like 304 stainless steel, carbon steel, and various laminated plastics. Their commitment to quality is evident in their use of advanced manufacturing techniques such as laser cutting, water jet cutting, and CNC machining. Furthermore, their customer-centric approach, including live online support and contract manufacturing services, truly sets them apart. They really do seem to prioritize both product excellence and client relationships, which is a good thing for any business.

For more information on precision manufacturing techniques, you might want to visit the National Institute of Standards and Technology (NIST) website.

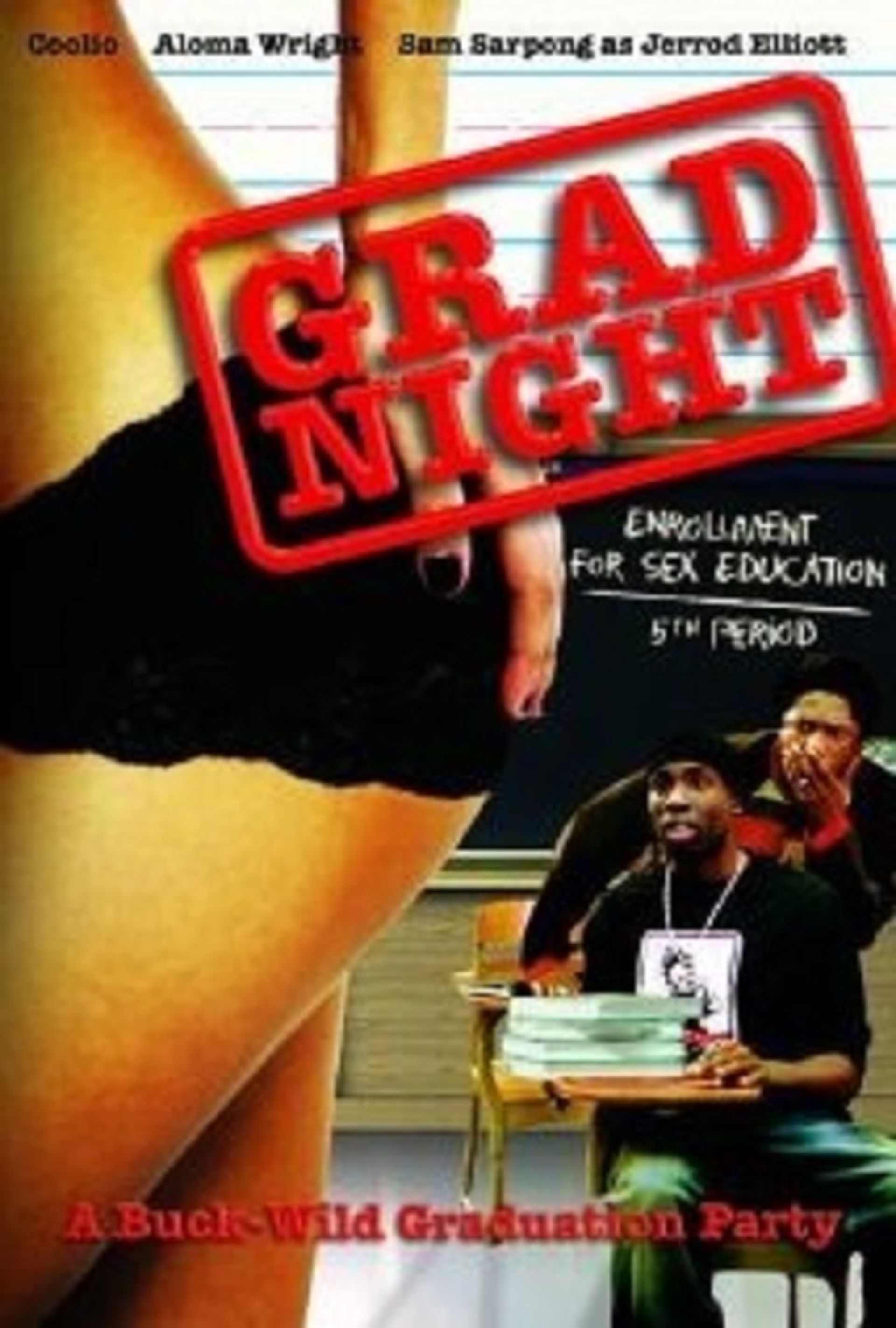

Aloma Wright – Movies, Bio and Lists on MUBI

Pictures of Aloma Wright

Pictures of Aloma Wright